What is the application of the tile trim profile?

What is the application of the tile trim profile?

The development and proliferation of trim profiles has echoed two major shifts in the ceramic

tile industry, including the transition from mortar bed installation to adhesive fixing and the

change in ceramic tile production techniques. Trim profiles are valuable tools for tile

installers, with the benefits ranging from simply improving the aesthetics and design options

to providing durability of tile assemblies.

Despite the fact that ceramic and natural stone tiles are very durable coverings, tiles are hard

rigid material and edges are prone to cracking and chipping when left unprotected. Tiles are

a popular choice for their hygienic and easy maintenance properties, however exposed tile

edges need to be protected.

In general, trim profiles for ceramic and stone tile applications feature two primary elements.

The first is an anchoring leg, which allows the profile to become an integral component of the

tile assembly within the tile adhesive bed. The second primary element of the trim profile is

the “body”, which forms the visible surface of the profile, finishing and protecting the tile edge.

Therefore, it is important when using trim profiles to select products that are specifically

designed for the application of ceramic and natural stone.

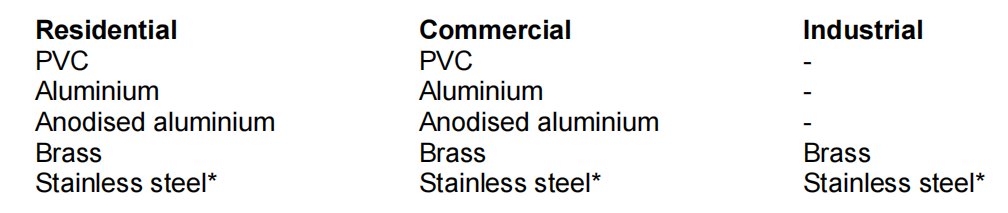

Trim profiles are available in a wide variety of materials, finishes and colours to suit various

internal and external tile applications from a design and aesthetic perspective; however it is

also important to consider the expected service conditions, e.g. mechanical stresses,

exposure to cleaners and chemicals, etc.

The following document is a general guide to the use of trim profiles within ceramic tile and

natural stone installations. Whilst there are a number of suppliers of profiles and trims within

common across all suppliers. For individual applications, or to verify suitability, it is

recommended that the product supplier is consulted for individual project suitability.

The most common profile materials encountered are PVC, aluminium, brass and stainless

steel. Whilst the manufacturer of the profile will determine its use and areas of application,

the following are generic guidelines.

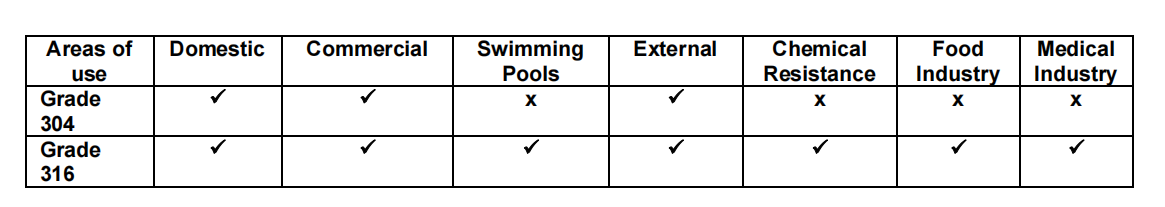

* Generally suppliers offer profiles and trims in grade 304 and grade 316 stainless steel

options. The selection of the different grades will depend on the application and exposure to

chemicals.

Stainless steel trims can sustain high mechanical stresses and is especially suited for applications

requiring resistance against chemicals and acids, e.g. swimming pools, hospitals and food

industry applications. All cleaning agents should be free of hydrochloric and hydrofluoric acid.

Stainless steel profiles are offered in various grades providing chemical resistance against

common substances that are encountered in tiled environments. Whilst stainless steel is

resistant to a variety of chemical substances it does not negate the need to employ a cleaning

regime for the profile(s).

The above chart is a generic guide to the use of stainless steel profile grades in tile

installations; verify individual suitability with the supplier.

Brass can sustain high mechanical stresses and is resistant to some chemical exposure. In

contact with air, solid brass will oxidize and develop a natural patina. This oxidation can be

cleaned with a suitable polishing agent.

Aluminium profiles should be verified for their suitability in the environment they are to be

used. Aluminium is sensitive to alkaline substances, which may result if the formation of

corrosion products (aluminium hydroxide). As cementitious materials in conjunction with

moisture become alkaline it is important to solidly bed the profiles and ensure all adhesive

and grout residue is removed from the profile. Oxidation films can be removed with a

common polishing agent.

PVC profiles should be checked with the manufacturer for suitability and chemical resistance.